Need someone to verify your Packaging or Labeling?

Packaging Inspections

Packaging inspections involve examining the physical packaging materials, such as boxes, bags, bottles, or containers, to ensure they are in good condition and suitable for protecting the product during storage and transportation. The packaging should be durable, secure, and free from any defects that could compromise the product's integrity or safety. Inspectors check for proper sealing, absence of leaks or damage, and appropriate use of protective measures like cushioning or tamper-evident features.

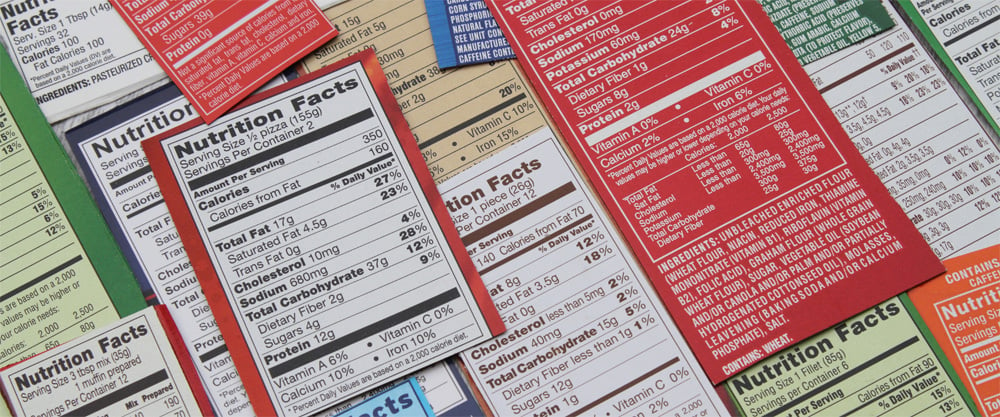

Labeling Inspections

Labeling inspections focus on verifying the accuracy and completeness of the information provided on the product labels. This includes ensuring that all mandatory labeling requirements are met, such as the product name, ingredients list, nutritional information, allergen warnings, usage instructions, and any applicable safety symbols or regulatory marks. Inspectors also check for the correct placement, legibility, and adherence of labels to packaging.

Packaging and labeling inspections

Packaging and labeling inspections are quality control measures conducted to ensure that products are properly packaged and labeled before they are distributed or sold to consumers. These inspections are crucial to verify that products meet regulatory requirements, comply with industry standards, and adhere to the specifications set by the manufacturer or brand.

During inspections, regulatory authorities, quality control departments, or third-party inspection agencies may be involved. They follow established guidelines and standards specific to the industry or product type. Inspectors may use visual inspections, sample testing, or specialized equipment to verify packaging and labeling compliance.

The goals of packaging and labeling inspections are:

- Compliance with regulations: Inspections ensure that products adhere to local, regional, and international regulations governing packaging and labeling. These regulations may cover aspects such as safety, consumer information, environmental considerations, and import/export requirements.

- Consumer protection: By verifying the accuracy and clarity of labels, inspections help protect consumers from misleading information, false claims, or potential health risks associated with product use or consumption.

- Brand integrity: Packaging and labeling play a significant role in brand recognition and customer trust. Inspections help maintain brand integrity by ensuring that products are presented in a consistent, professional manner, with accurate and attractive packaging and labels.

- Supply chain efficiency: Properly packaged and labeled products facilitate efficient logistics and supply chain management. Inspections help identify packaging or labeling issues early on, reducing the likelihood of disruptions, delays, or product recalls.

Non-compliance with packaging and labeling requirements can result in legal penalties, product recalls, damage to brand reputation, and potential harm to consumers. Therefore, inspections are essential to mitigate these risks and ensure that products meet the necessary standards for safety, accuracy, and regulatory compliance.