Improve your On-Time In-Full (OTIF) logistics performance.

Incorporate the World's Largest Inspection Marketplace into your logistics.

Improve your OTIF through accurate pre-shipment inspections. Get a quote for an inspection or contact us and see how we can integrate into your logistics.

Find out more about our integration - Click here to get started!

WE have a worldwide footprint of 3rd party Inspection Professionals AND companies All available from our dashboard.

Use our global footprint to your advantage!

Use our inspections services in your logistics and supply chains!

Inspections play a crucial role in improving On-Time In-Full (OTIF) logistics performance by ensuring that shipments and processes meet the required standards and specifications.

Find out more - Click here to get started!

Here's how inspections can help enhance OTIF logistics:

Quality Control: Inspections help verify the quality of goods and materials before they are shipped. By identifying defects, damages, or discrepancies early in the process, companies can avoid delays caused by rework or rejection of subpar items. This contributes to delivering products that meet customer expectations and reduces the likelihood of late or incomplete shipments.

Accuracy of Orders: Regular inspections at different stages of the supply chain, such as during picking and packing, help ensure that the correct items and quantities are being prepared for shipment. This minimizes errors and the need for corrections, leading to accurate and complete orders reaching customers on time.

Documentation and Compliance: Inspections assist in confirming that all necessary documentation, such as shipping manifests, customs paperwork, and regulatory requirements, are in order. This reduces the risk of delays due to non-compliance or missing paperwork, which can lead to clearance issues at customs or other regulatory checkpoints.

Packaging and Handling: Proper packaging and handling inspections prevent damage to goods during transit. By using appropriate packaging materials and techniques, companies can safeguard products from potential mishandling, ensuring that shipments arrive intact and ready for use.

Supply Chain Visibility: Inspections provide real-time visibility into the status and condition of goods throughout the supply chain. This enables better tracking and monitoring of shipments, allowing companies to proactively address any issues that may arise and make necessary adjustments to ensure on-time delivery.

Risk Mitigation: Inspections help identify potential risks and bottlenecks in the logistics process. By addressing these issues early, companies can take proactive measures to mitigate risks and prevent disruptions that could lead to delivery delays.

Continuous Improvement: Regular inspections offer valuable data and insights that can be used to analyze trends and patterns in logistics performance. This information can drive continuous improvement efforts, allowing companies to optimize their processes and achieve higher levels of OTIF performance over time.

Supplier Relationships: Inspections can be conducted at supplier facilities to ensure that they meet the required standards for quality and reliability. By working closely with suppliers to address any issues, companies can enhance their overall supply chain efficiency and reduce the chances of delays caused by external factors.

In summary, inspections contribute significantly to achieving OTIF logistics by ensuring product quality, accuracy, compliance, and supply chain visibility. They enable companies to identify and address potential issues early, leading to smoother operations and improved customer satisfaction.

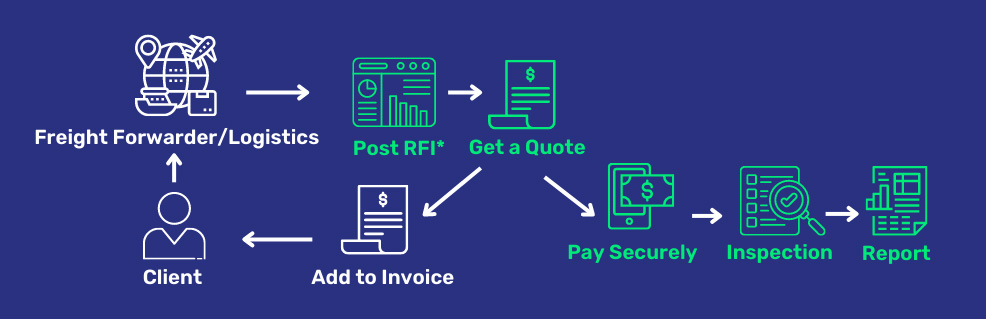

If you are a logistic service provider you can now add inspection services for you clients!

Create an account, request an inspection get multiple competitive quotes, pay securely, get the inspection and report done in your timeline!

600

Registered QC Companies

165000

Available Manpower

90

Countries we have presence